Directional Drilling Technologies

XR Team innovates and develops downhole drilling technologies through its XR Lateral company. Our primary purpose is to assist E&P Companies to better drill directional and horizontal wells with emphasis on shale plays. The company focuses on drilling efficiency and placement accuracy in the build and lateral sections of horizontal wells by introducing new technologies into the steerable motor BHA.

Our technologies reduce drilling cost, extend lateral reach, and provide wellbore quality that enhances hydrocarbon production.

Traditional directional drilling practice has too often accepted OverBend™ high bend angle BHAs that impart excessive vibration, dogleg severity, and borehole degradation.

Our core technology provides predictable, as planned build rates using unprecedented MicroBend™ low bend angle BHAs. This technology sets up to provide smoother transitions, better tool-face control, more efficient use of power, and improved hole cleaning, resulting in higher ROP, longer tool life, and smoother wellbores.

XR Lateral is actively developing drilling solutions with three IP protected innovations:

· Compound Geometric Guidance (CGG)

· Dynamic Lateral Pad (DLP)

· Laterally Oriented Cutting Structure (LOCS).

CGG Technology

Our CGG Technology has been field testing in the Permian Basin.

Model of our IP protected CGG directional technology

2.12° Bend Machining Illustrates destructive BHA Behavior

Several experts have identified harmful ledges created in the lateral when drilling is switched from rotate mode. These ledges negatively influence sliding efficiencies further down the lateral and torque when rotating ahead. Please see Stockhausen IADC/SPE 151248 for further discussions and drilling test examples.

Eccentric motion at bend point

Video demonstrates lathe set up for turning an off-axis angle on a 2.12° fixed bend housing. It also illustrates the eccentric motion translated to the bit during rotate drilling with a downhole mud motor.

OUT OF CUT DRILLING DISFUNCTION

Through extensive modeling XR Team identified OCDD as the primary contributor to bit damage in rotate mode with a bent housing motor. As the assembly is rotated the some of the cutters of the drill bit cyclically exit and reenter the rock, causing recurrent impact damage to the cutting structure. In an effort to address this problem bit designers have increasingly “hardened” drill bits with depth of cut limiters, impact limiters, and back up cutting structure, all of which reduce the efficiency of the drill bit.

None of these corrective measures address the root cause which is the bend angle of the assembly driving OCDD. Higher bend angles increase the incidence of OCDD damage.

Directional Drilling Technologies

Compound Geometric Guidance(CGG)

Patent Pending, 7 issued design patents

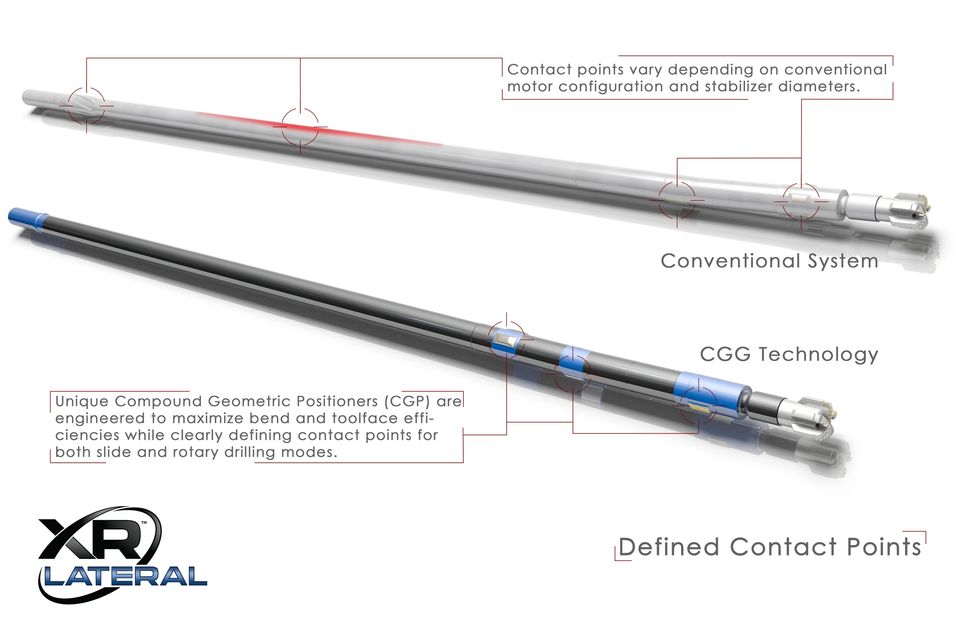

This technology provides specific support structures to the BHA to enable desired build with reduced bend angles. It also provides support in rotate.

Eccentric Rotation of Drilling Mud Motor Including XR Team's CGG Technology

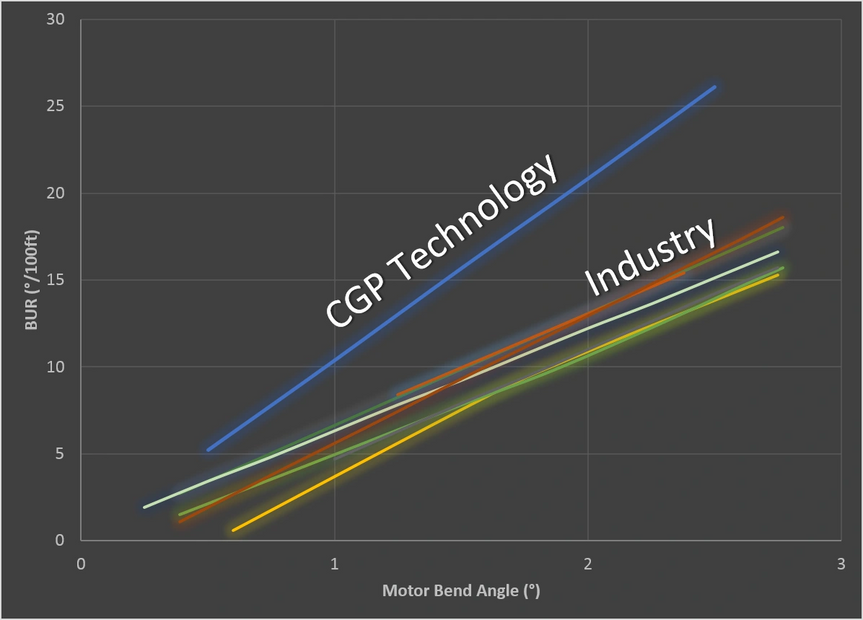

CGG (Compound Geometric Guidance) enables a 1.5° bend angle drilling motor capable of drilling 12°+/100' curve sections and drilling a near-gage hole while rotating. The CGP's (Compound Geometric Positioners) optimally position the motor in the hole for maximum bend efficiency. The major drilling benefit is an increase in rotary RPM while rotating and the potential to directionally drill while rotating due to a closer to gage hole and controlling rotate tendency with parameters and contact points.

Eccentric Motion of a Conventional 2.25˚Fixed Bend Drilling Motor

Conventional motor with a 2.25° bend angle drilling motor capable of drilling 12°+/100' curve sections but drilling an excessively large, over-gage while rotating. The eccentric motion demonstrates Out of Cut Drilling Dysfunction (OCDD) which can lead to premature bit failure and other BHA component failure.

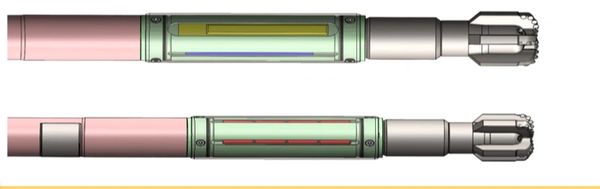

XR Team's DiaGlide + CGG (Compound Geometric Guidance) Technology

DiaGlide + CGG enables a 1° bend angle drilling motor capable of drilling

12°+/100' curve sections and drilling a near-gage hole while rotating. The use of DiaGlide bearings allows for a reduction in Bit-to-Bend and thus bend angle combined with the bend angle reduction from deploying CGG technology results in an ultra low bend angle of 1°. The major drilling benefit is no limitation on rotary RPM while rotating and the potential to directionally drill while rotating due to a near-gage hole and controlling rotate tendency with parameters and contact points.

Modified Bottom Hole Assembly

Patent Pending, 3 issued design patents similar to CGG but with alternative asymmetries.

Dynamic Lateral Pad (DLP)

Patented and Patent Pending mandrel driven “push the bit” technology aligned with the scribe line improves build efficiencies with reduced bend angles.

XR Team's DLP (Dynamic Lateral Pad) Technology

A mechanically driven pad, adaptable to a drilling motor, adds side force in the steering direction allowing for a reduction in motor bend angle.

Cam Follower (for use on DLP)

Patented and Patent Pending, Diamond on Steel mandrel engagement drive mechanism

Rotational Tendency (DLP method)

Patent Pending, employs DLP in rotate mode to improve course holding on a given trajectory

Laterally Oriented Cutting Structures (for use with DLP)

Patented, PDC bit cutting structures to enhance steering response to impulses from DLP

Benefits to Operator

Construct quality cost effective wellbores with low NPT that do not negatively affect the production capability and/or increase completion and production lifting costs are a major challenge for Shale Operators.

XR Team studied this issue and realized drilling dysfunction caused by high bend angle mud motors is the major contributor to poor wellbore quality. This discovery drove our innovation path, leading to technologies that reduce the bend angle by as much as 50% over industry norms.

Additional Technologies

Sensors

XR’s Combo Bearing motor technology provides heretofore unavailable space for the deployment of sensors in the lower bearing housing without increasing the critical bit to bend length.

XR Dynamics

Copyright © 2021 XR Team - All Rights Reserved.

For additional information, contact 713-314-0678

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.